Seawater Air Conditioning (SWAC)

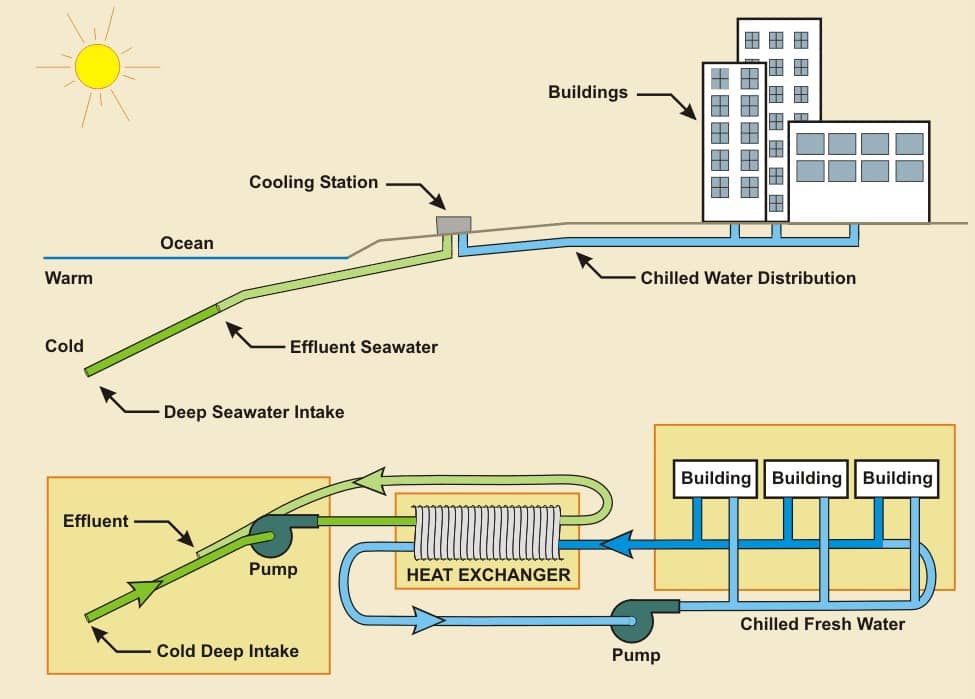

Seawater Air Conditioning (SWAC) is a form of deep water source cooling that takes advantage of available deep cold water from the ocean to replace conventional AC systems. Other forms of deep water source cooling systems utilize cold lake (deep lake water cooling [DLWC]) or river water as the cold source.

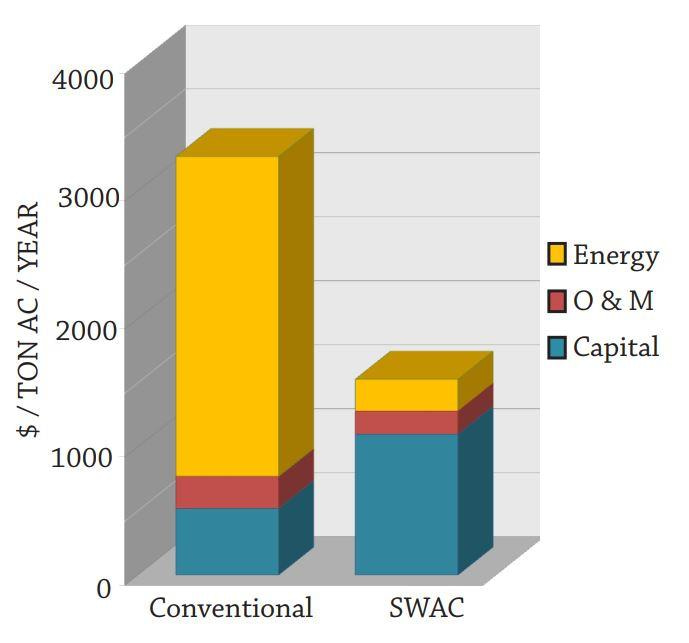

SWAC can reduce electrical consumption by 80 to 90 percent in many cases. Simple payback can be from three to seven years, and long term costs can be half that of a conventional air conditioning system.

Pipeline Technologies and Services

Makai Ocean Engineering offers a full range of engineering services for seawater air conditioning analysis and implementation. Makai can provide technical and economic SWAC assessments, offshore surveys, environmental analysis, review of permit needs, deep water pipeline design, conceptual through final engineering design, cost estimates for construction and operation, and construction management.

Makai's engineers are experts in large diameter high density polyethylene (HDPE) pipeline design. For decades, Makai has been a world recognized leader in Seawater Air Conditioning (SWAC) and Ocean Thermal Energy Conversion (OTEC), two renewable energy technologies that use deep seawater as a renewable energy resource.

SWAC Benefits

- Economic payback can be as low as 5 years

- Energy for cooling reduced by 90% in some cases

- Future rate increases have little impact on SWAC

- Pipeline & heat exchangers are long lasting and corrosion resistant

- Green tax incentives & low-rate municipal revenue bonds available

- Potable water use is eliminated

Installed SWAC Systems

Makai has been involved in SWAC system design and development since the 1970s. Makai’s engineers have been involved in most of the SWAC/ Deep Water Source Cooling projects worldwide.

The key cost and risk component of any SWAC system is the offshore pipeline. The lack of a low-cost methodology for the installation of these pipelines prevented SWAC development in the 1970’s and 80’s. Today, the technology for the successful installation of large diameter (>2 meter) pipelines to depths of 1,000 meters and greater is available. Numerous successful deep seawater intake pipelines have been designed by Makai that were installed and operated successfully. Many of these pipelines have been for Seawater Air Conditioning (SWAC) systems.

A summary of SWAC projects installed with Makai’s support are included below:

Bora Bora SWAC

Makai engineered a complete SWAC system for the InterContinental Bora Bora Resort in French Polynesia for supplying 450 tons of AC.

More Info

This demanding project involved a 2,300 m long intake pipeline going to 900 m depth on a seabed with slopes up to 60 degrees. This system pumps 1,200 gallons per minute (gpm). This project was completed in 2006, and has been in operation since May of that year.

Bahrain District Cooling

In 2005, Makai designed intake and discharge pipelines to provide seawater to the Bahrain Diplomatic Area District Cooling Project’s air conditioning plant for condenser cooling.

More Info

Seawater drawn from the Arabian Gulf is slightly warmed and then returned into near shore waters. The system, owned by Tabreed Bahrain, features a 63” (1.6 meter) diameter by 2240’ (683 meter) long intake pipeline, and a 55” (1.4 meter) diameter by 5104’ (1556 meter) long outfall pipeline with a 20 port diffuser, operating at a flow rate of 60,000 gallons per minute (3.79 m3/sec).

Toronto District Cooling

In 2003, Makai performed significant design aspects for the three deep water intakes for ENWAVE’s Deep Lake Water Cooling Project in Lake Ontario. Each HDPE pipeline is 5 km long and 1.6 m in diameter.

More Info

The deep (115 meter) intakes provide cold water for air-conditioning buildings in downtown Toronto and the municipal drinking water system with a maximum capacity of 58,000 tons. The system provides water of higher purity than is provided by the current intakes that obtain water from shallower depths. Each HDPE pipeline is five km long and 1.6m (63″) in diameter. The pipelines were installed during the summer of 2003.

Cornell University Lake Source Cooling

Makai was selected by Gryphon International Engineering Services and Cornell University to design a 63″ diameter HDPE intake and a 48″ diameter outfall pipeline in Cayuga Lake, NY to provide 20,000 tons of centralized cooling for the university.

More Info

The intake pipeline is two miles long with an intake at 250′ depth. The pipeline provides 32,000 gpm of cold water and has a 75-year lifetime. Construction was completed in 1999. The system has been operating since 2000 and has cut electricity needed for air conditioning by 87%.

Interested in Makai’s SWAC Services?

ReACH OUT!

Contact us by sending in this form any time you need professional support or have any questions. You can also fill in the form to leave your comments or feedback for Makai’s team.